Hello, your privacy is important to us. Uniview websites use cookies to store info on your device and create the most secure and effective website . By continuing to use our websites, please accept the cookies could be stored on your device, which outlined our cookie policy and privacy policy .

-

- 中文版

- USA

- 한국어

- Tiếng việt

- Русский

- Polski

- Français

- Turkish

- Español

- Italiano

- 日本語

- العربية

- ไทย

- bahasa Indonesia

- Portuguesa

Products

Network Cameras

_1036463_651984_0.png)

Easy Series

Popular picks for entry-level needs like homes and small shops.

Prime Series

More advanced features for top performance in various scenarios.

Pro Series

Packed with smart tech to deliver a premium user experience.

Owlview Series

F1.0 lens or 1/1.8" sensor, and Wise-ISP for ultra-clear night vision.

MultiView Series

All-in-one cameras offering complete scene coverage and rich visual details from multiple angles.

OmniView Series

Ultra-wide view cameras that eliminate blind spots and simplify installation for smarter protection.

_1036463_651984_0.png)

Solar Series

Solar-powered cameras designed for reliable outdoor visibility in off-grid or hard-to-wire locations.

Tri-Guard Series

Tri-Guard series combines Smart Intrusion Prevention, ColorHunter, and Active Deterrence to prevent crimes at night.

PTZ Cameras

Prime Series

Prime series PTZ cameras are equipped with LightHunter technology for bright and clear image in the ultra-low environment.

Pro Series

Pro series PTZ cameras are equipped with professional features for vertical market, such as 45x optical zoom, gyroscope, optical defog and so on.

Positioning System

Perfect choice for monitoring large open areas such as border security, harbor, and city monitoring project.

Easy Series

Products from the Easy series are the most popular choices for entry-level applications such as residential and small retail stores.

Network Video Recorders

Easy Series

Excellent in input and video storage of several IP cameras. The friendly design of device enclosure and software GUI help operator to achieve a better experience.

Prime Series

Equipped with many practical functions and powerful decoding ability. Fits well with projects, empowers the SMB market.

Pro Series

With large enough capacity, stability and expansibility, Pro Series provides the highest level of performance for vertical market.

Partner

Partner Program

Dealer Partner Program

Uniview Dealer Program provide exclusive intimate services for our dealer partners who mainly

focus on distribution and reselling businesses.

Solution Partner Program

With Uniview Solutions Partner Program, we enable growth and build

relationships while providing a comprehensive solution for clients.

Technology Partner

Technology Partner is the industry leaders that Uniview cooperated with. We support integration with third-party partners to meet users' needs for integration.

X

X

Products

Products

Digital Video Recorders

Digital Video Recorders

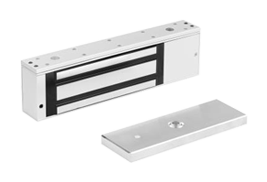

Edge Intelligence

Edge Intelligence

Solutions

GLOBAL / ENGLISH

GLOBAL / ENGLISH

_1013732_651984_0.png)